CREMATION FURNACES

ZEUS cremation ovens.

With its high level performance, ZEUS is complete and reliable and is one of the highest performing cremation plants the market has to offer.

The cremation chamber is available in an “indirect flame” version to guarantee no contact between the flame and coffin, and a direct flame version.

The afterburner chamber, always present, is sized to guarantee gas remains for over two seconds, at a temperature of over 850°C.

The cremation process is fully automatic and controlled by a computerized system with microprocessor, through which the operator can monitor all operations of the plant and limit interventions to general surveillance, in addition to introducing coffins and removing ashes.

The ZEUS system is designed to collect, separately from the ashes, molten zinc during the cremation phase.

Since it is necessary to deal with emissions limits that are increasingly stricter, the plant is usually fitted with a fume treatment line sized and designed according to specific needs and where necessary it can be associated with an energy recovery system.

Ciroldi technical support is able to perform ordinary and extraordinary maintenance quickly to guarantee constant operation.

.

ZEUS CREMATORS MODELS

ZEUS 1000 BS

Compact cremator, easy to install and simple to run.

Daily productivity suitable for small/medium-sized cities.

ZEUS 1000 SP

This cremator is complete with heat recovery system, fume filtering and computerised management of the entire process.

Daily productivity suitable for medium-large requirements.

ZEUS 1000 ZN

This cremator is complete with heat recovery system, fume filtering and computerised management of the entire process.

Daily productivity suitable for medium-large requirements and with the possibility of treating boxes with zinc.

ZEUS 1200

This cremator is complete with heat recovery system, fume filtering and computerised management of the entire process.

Daily throughput suitable for medium to large contexts and with the possibility of processing XXL corpses.

COMPUTERISED MANAGEMENT AND CONTROL SYSTEM

Fully automatic with a user-friendly PLC touchscreen operator interface, it comes complete with a system for measurement, acquisition and recording of the process parameters and transmission to a PC station, as well as a remote service system.

THE SERVICES CIROLDI OFFERS

RESPECT FOR THE ENVIRONMENT

Constructing cremation furnaces today means unfailingly respecting the environment. Ciroldi strictly adheres to all the emission values pre-established by the most stringent international environmental protection standards.

Technical data of our crematory ovens

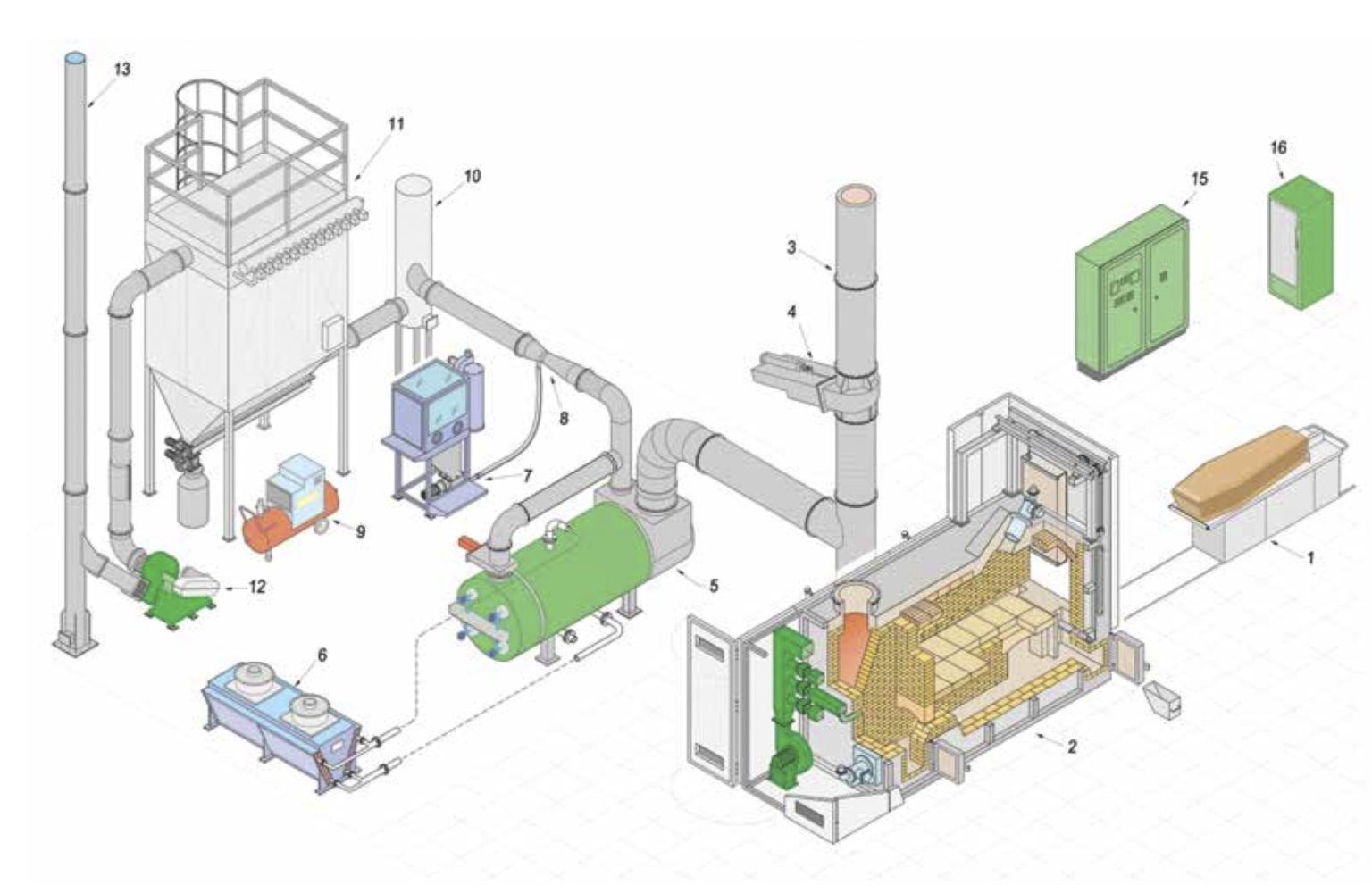

1. Autoloader

2. Cremation oven

3. By-pass chimnery

4. By-pass valve

5. Heat exchanger hot fume / hot water

6. Dry cooler

7. BiCa dispenser

8. Venturi

9. Compressor

10. Reactor

11. Bag filter

12. Fan

13. Chimnery

14. Protection door

15. Ash grinder

16. Control cabinet